How Technology Can Safely Help Manufacturing Businesses Thrive

September 16, 2021

We can all agree that manufacturing is one of the most prominent aspects of the US economy. At the same time, it is increasing each year. Compared with 2009, it increased approximately twenty-seven percent.

Even though it comes with specific difficulties depending on numerous factors due to international and economic trends and job cuts, things are continually changing.

That is why numerous manufacturing industries have implemented technological advancements. You should click here to learn more about manufacturing IT solutions you can implement to take your business to the next level.

Keep in mind that the manufacturing industry changed due to consumer demand. Since they wish for better and faster products that are both unique and customized, it is vital to keep them happy along the way.

New advances in manufacturing technology affect customer demand, mainly because implementing CMMS or a computerized maintenance management system can create a more efficient and productive situation.

Remember that CMMS can easily track breakdowns, inspections, and maintenance, which will reduce potential system disruptions. Therefore, you do not have to manually follow changes and problems because the system will handle everything from a single place.

That way, you can boost overall productivity, reduce maintenance costs, streamline historical data, trend reports, and workforce.

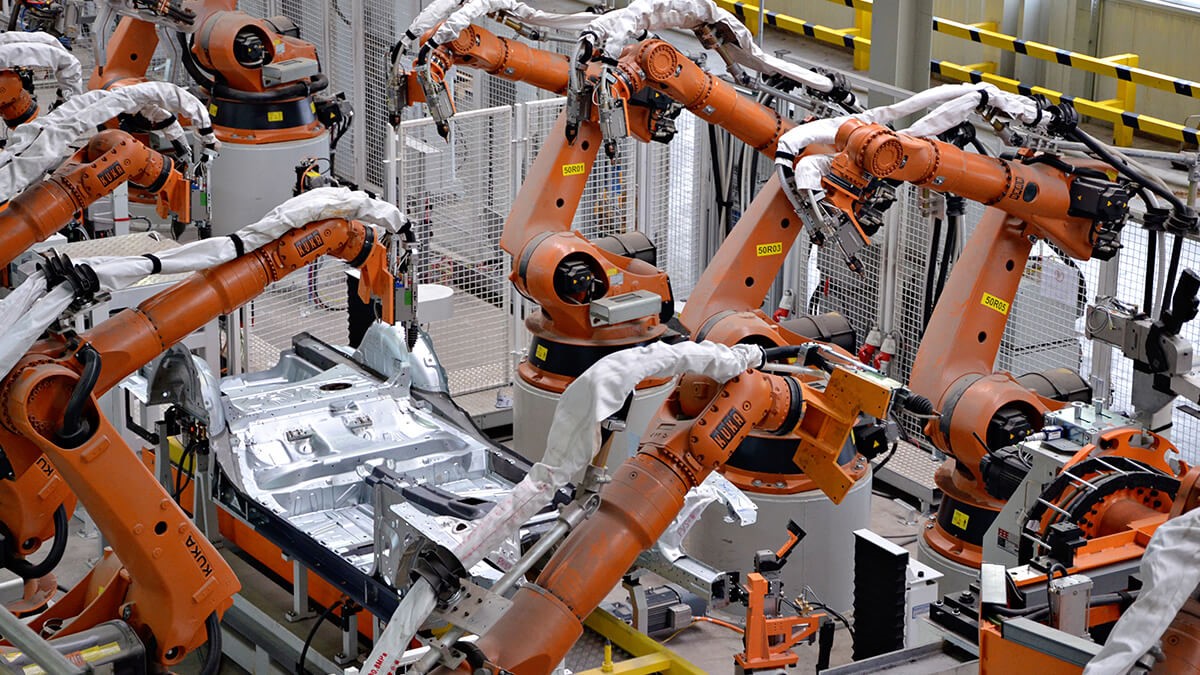

Big Data and Internet of Things (IoT)

It is vital to implement devices that can talk to others or the Internet of Things with CMMS technology. That way, you can easily connect to the Internet, which will enable remote monitoring and automation.

Compared with manual checkups, implementing IoT will help you connect each device with another, which will help you monitor the progress and other aspects.

Remember, you can aggregate and collect a mass of information or big data about your system with these connections. The main goal is to take advantage of information by analyzing and measure it, which will help you boost overall efficiency and productivity.

Smart Products

Most consumers nowadays are demanding connected, responsive, and intelligent products, which means smart options. We are talking about wearable technology, connected cars, and smart lighting, among other things.

The main idea is that customers enjoy these products and technology, which means they will use them in daily activities.

You should check out this site: https://en.wikipedia.org/wiki/Industrial_internet_of_things to learn more about smart products.

Since products are becoming connected and smarter than before, manufacturers must find ways to mass-produce the technology, primarily because of the continual evolution and improvement.

As a result, the process will change your manufacturing business model and get professional employees to help you out. Therefore, you will not be able to rely on assembly-line created products.

Instead, you should find professional and specialized talents to provide you peace of mind.

Technology and Workforce

Although technological advancements are essential for boosting your products and manufacturing processes, the implementation will affect the workforce.

For instance, most manufacturers have a moderate or severe shortage of skilled and qualified applicants for important positions.

If the trend increases, the skill gap will not be able to fulfill two million manufacturing jobs in the next decade.

For instance, 3-D printing is becoming more affordable than before, which means it requires more materials and less time to produce complicated designs.

The products will not require assembly-line processing but skilled engineers who can manufacture and design shapes.

It is simple to determine that a past regular workforce will change into professional and expert professions. Nowadays, employees within the manufacturing industry are highly paid and skilled. Generally, they are earning more than twenty-five percent than average US employee.

As a result, technology is affecting the jobs to increase salaries but in return needing skilled employees.

Technological Advancements That Are Affecting Manufacturing

1. Cloud Computing

In today’s world of modern manufacturing, implementing cloud computing processes is essential. Owners are still asking themselves whether they should choose regular data as before or choose cloud.

Remember that manufacturing platforms require regular re-investment, upgrading, and maintenance to keep up with the demands and complexities your customers need. However, media use outdated technologies that are not efficient in today’s world.

Therefore, the main goal is to unify your data and business no matter the locations, which will help you get additional scalability, accessibility, agility, and security. That way, you can focus on streamlining and taking your business to the next level.

Clouds can help you on core focus, which will help you change your business and reduce expenses for annual maintenance and functionalities that will provide you significant downtime.

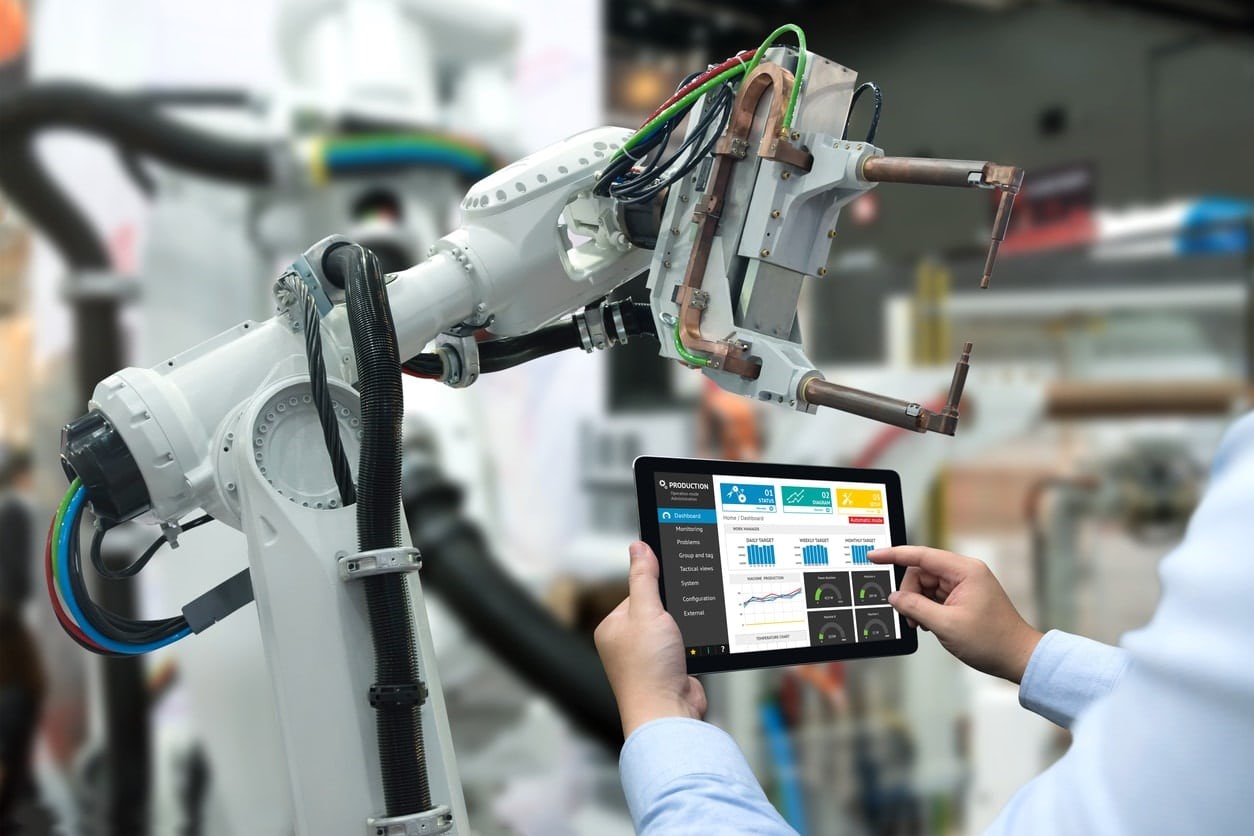

2. Mobility

Since you will boost accessibility by implementing cloud computing, you can use mobile devices to enter a production environment, take relevant documentation anywhere you are.

At the same time, advancements in industrial wearable tools such as smart glasses will help you get a hands-free and affordable experience for your factory employees.

Since the production environment uses a wide array of sensors, beacons, RFID, and other communication means, you can ensure more effective visibility in production status, machine efficiencies, and movement while sharing relevant data through a wireless connection.

The technology will help you boost your business productivity, which will help you out with a wide array of processes.

3. Real-Time Analytics

You should know that manufacturers can generate the data in real-time, which allows them to get relevant information whenever they want. You must find ways to harness the data to help you create autonomous decisions, insights, and predictive behavior.

As a result, you will improve efficiency, which is an essential consideration to remember. Taking advantage of analytics will help you determine relevant data points, connect them, and use the information for boosting your business.

Since analytics are becoming more meaningful, they are crucial for managing the Big Data world. Generally, manufacturing intelligence and analytics create machine learning, which is an essential aspect of creating a strategy.

4. Industrial IoT

Similarly, as mentioned above, connectivity will help you deliver valuable data, insight, and the ability to make more informed and faster decisions.

Technological innovations, including smart devices, connected sensors, machine learning, and internet connectivity, will help you improve manufacturing processes and equipment while generating relevant data you can use afterward.